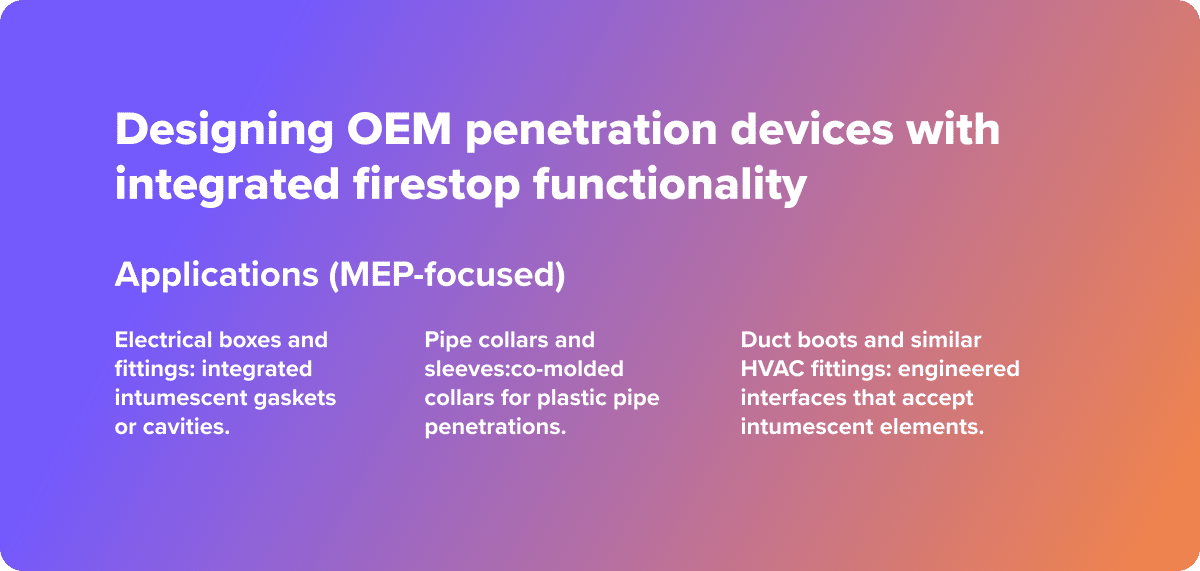

How OEMs can build in intumescent penetration seals that can be tested and, where applicable, listed in accordance with UL 1479 / ASTM E814 when installed per the listing.

Introduction: Design Fire Protection In, Don’t Patch It On

In many projects, mechanical, electrical, and plumbing (MEP) penetrations are installed first and firestopped later with field‑applied caulks, wraps, paints, or putties. While factory application of those products is also possible, an alternative approach is gaining traction with OEMs: integrate intumescent firestop functionality directly into the penetration device or fitting during product design.

This article explains how integrated intumescent solutions support UL and ASTM fire tests for MEP penetrations, when they complement (not replace) field‑applied methods, when and only where the listing permits.

The limits of a purely field‑applied approach for MEP penetrations

Field‑applied firestop systems are proven and widely used, but they can introduce variability that OEM integration helps control:

- Process variability. Results depend on installer technique, joint preparation, and adherence to the listing’s details.

- Sequencing complexity. On both conventional and modular/prefab projects, penetrations may be concealed or hard to access by the time sealants are scheduled, adding coordination overhead. Factory sealing is feasible but adds separate steps outside the core product design.

- Documentation load. Inspectors must verify the exact listed system, materials, and installation details at each penetration.

Integrated devices shift much of that work into product engineering and testing, making outcomes more predictable while keeping code compliance intact.

Why integrate intumescent firestop materials into MEP components?

Intumescent materials expand under heat to help close annular spaces and limit fire and smoke spread through penetrations. When the intumescent polymer is engineered into the OEM component, you can:

- Deliver repeatable geometry at the point of penetration. The intumescent is placed where it’s needed, with controlled thickness and volume.

- Support tested performance. Integrated assemblies can be designed and tested to UL 1479 / ASTM E814 for through‑penetrations and coordinated with assembly ratings from UL 263 / ASTM E119.

- Reduce, but not entirely eliminate, dependence on field‑applied products. In many listings, the integrated device serves as the primary firestop element, with sealants used only where the listing calls for them.

Standards that guide design and testing

For through‑penetration firestop devices and materials, OEM engineers typically align with:

- UL 1479 / ASTM E814: Fire tests for through‑penetration firestops, including F‑ratings (fire endurance), T‑ratings (temperature transmission), and L‑ratings (air leakage for smoke control).

- UL 263 / ASTM E119: Fire‑resistance ratings for walls/floors that the penetration passes through.

- ICC & NFPA codes: Require tested and listed solutions matched to conditions of use.

Always use the exact tested/listed system for the specific penetration and assembly; final acceptance rests with the Authority Having Jurisdiction (AHJ).

Key design considerations:

- Performance under fire exposure. Expansion onset temperature, expansion ratio/pressure, and char integrity drive results in UL 1479 / ASTM E814 testing.

- Part geometry & section thickness: Thicker intumescent sections deliver more expansion capacity and load‑bearing char.

- Integration method. Co‑molding, insert‑molding, over‑molding, or mechanical retention. Choose a path that keeps the material where the listing requires it.

- Material & substrate compatibility. Ensure the intumescent polymer bonds or locks in with your plastics or metals and does not impair normal service.

- Labeling & installation clarity. Mark the device and supply instructions that map directly to the listing for easy inspection.

Quick Design Checklist for Engineers:

- Defined geometry and section thickness.

- Target expansion onset temperature.

- Expansion pressure and char strength.

- Compatibility with substrate materials.

- Clear labeling and installation instructions aligned with tested listings.

SafePassage™ for OEM MEP penetration devices

SafePassage™ is Pyrophobic’s patented, tunable intumescent thermoplastic platform for OEM integration. Unlike brittle boards or purely field‑applied sealants, SafePassage™ can be molded or extruded into the device itself, such as collars, sleeves, electrical enclosures, grommets, or other through‑penetration fittings, and tailored to meet UL 1479 / ASTM E814 requirements for the intended use. It gives OEMs a design‑stage path to consistent, testable firestop function.

Side‑by‑side: field‑applied vs. integrated OEM device

| Aspect | Field‑applied sealants/wraps/putties | Integrated OEM penetration device (e.g., SafePassage™) |

| Where the firestop is created | In the field or at the factory as a separate step | Engineered into the device (instead of being applied in the field) |

| Variability | Depends on installer technique and access | Geometry and placement controlled by design |

| Documentation & inspection | Each penetration must be matched to a listed system | Device markings and instructions map to listing |

| Reliance on additional products | Often primary, may require accessories | May reduce or eliminate sealants where listing permits |

| Use in prefab/modular | Feasible; adds a task to factory workflow | Penetration arrives with firestop function included |

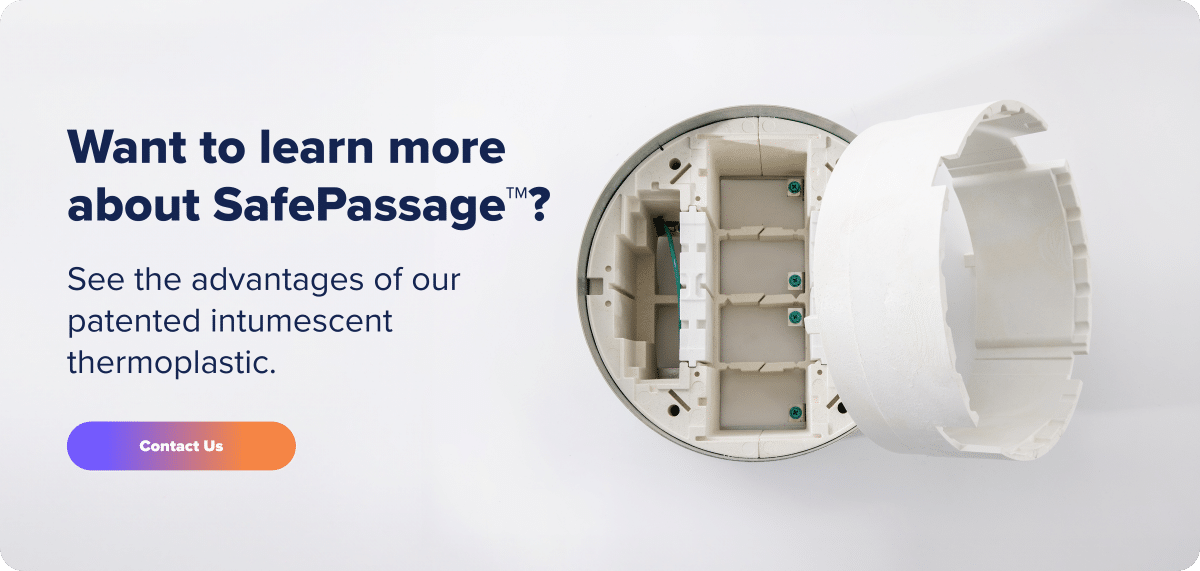

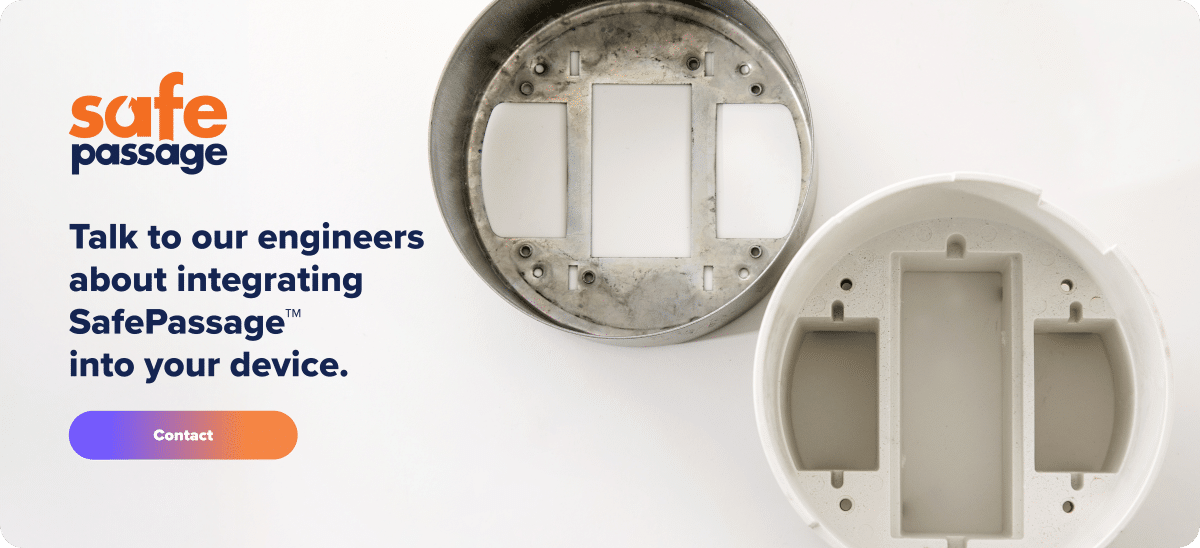

Example: A fire-rated electrical box with intumescent gaskets

An OEM electrical box can integrate SafePassage™ intumescent gaskets so that, when the assembly is tested in a rated wall or floor, it meets UL 1479 / ASTM E814 requirements, including relevant L‑ratings where smoke control is required. By designing the intumescent material into the box or cover, OEMs can reduce reliance on field‑applied sealants, delivering a consistent, inspector‑friendly solution.

Where this helps on modular and conventional jobs

Both conventional and modular/prefab projects benefit from penetration devices that are born firestop‑ready.

- In modular work, integrated devices streamline factory workflows and simplify inspection at set.

- In conventional jobs, they reduce field variability and documentation complexity.

Conclusion & next steps

Passive fire protection for penetrations has long been code‑mandated. The opportunity now is to design it earlier. By integrating intumescent firestop materials into MEP components and testing to UL 1479 / ASTM E814, OEMs can deliver repeatable, inspector‑friendly products that align with UL 263 / ASTM E119 assemblies and modern construction methods.

FAQ

Q1: What are intumescent penetration seals?

Materials that expand under heat to help close annular spaces around pipes, ducts, and cables, supporting fire and smoke containment at rated assemblies.

Q2: Which standards apply?

Primarily UL 1479 / ASTM E814 for through‑penetrations, coordinated with UL 263 / ASTM E119 for assembly ratings. Where smoke control matters, the UL 1479 L‑rating defines acceptable air leakage. Always follow applicable ICC and NFPA codes.

Q3: How can OEMs support compliance in prefab or conventional construction?

Engineer the penetration device with integrated intumescent elements, test it as a system, and supply clear markings/instructions. This reduces field variability and streamlines inspection.

Q4: What makes SafePassage™ different?

SafePassage™ is a patented, tunable thermoplastic intumescent platform OEMs can mold or extrude into their components and design to meet UL 1479 / ASTM E814 firestop requirements.