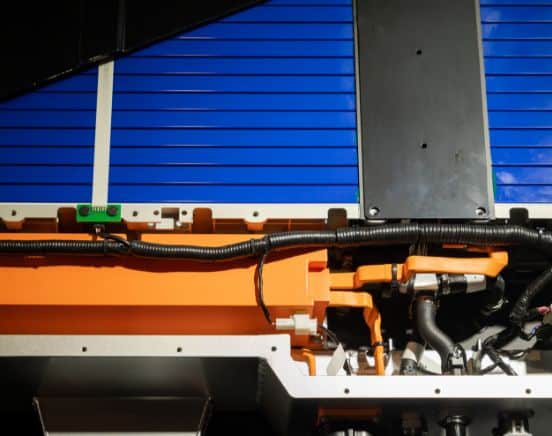

LithiumPrevent’s proprietary intumescent polymer technology is injection molded or extruded to form fire-resistant battery pack components. The technology, combined with innovative designs and our team’s expertise, delivers superior thermal runaway containment and propagation prevention for OEM battery systems.