When developing or upgrading to a fire resistant Pack Design Specification, consider the following 10 requirements:

1. Prevent Thermal Runaway Battery Propagation

Provide significant separation between cells to segregate runaway events and provide a radiant barrier between cells.

2. Vent Flammable electrolyte outside of the pack.

Venting electrolyte and stopping the propagation of heated electrolyte to cells adjacent the runaway cell has proven critical in preventing a cascading event as it progresses. We see there is a delay in the event that continues if the electrolyte spills over. If the electrolyte venting can be controlled and the electrolyte cooled by passing through the Lithium Prevent material, the event is contained.

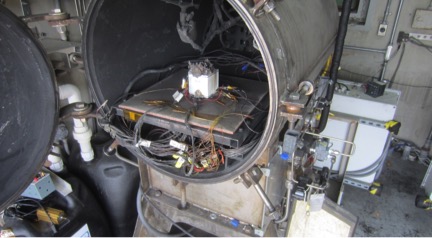

This is the NASA BP Cell pack. The rupture disk was in line with the vent holes. The 4 mm wall thickness provided good thermal separation between cells to prevent cascading.

3. Prevent transfer of internal heat to normal ignite-able combustibles outside of the pack

4. Protect from external fire.

External fires can consume lithium batteries causing Class A fires to graduate to Class D fires (special metals fire). Preventing thermal transfer of heat from inside the pack as well as exposure of the pack to an external fire limits the amount and type of fuel that can combust.

The pack materials must prevent penetration by a flame of 1700°F for 5 minutes, and the peak temperature measure at 4inches above the sample must not exceed 400F.

5. Control the Explosive gases of the runaway batteries.

6. The pack design must largely maintain its original structure after thermal runaway and explosive event.

7. Test for specific cell chemistries and cell construction combinations

All cells in thermal runaway produce a pressure pulse. The larger the cell size, generally, the larger the pulse. Lithium Prevent design has withstood a pressure pulse as large as 20 PSI.

8. Physical Abuse

Abuse testing standards such as UN 38.3 [2] have attempted to capture all of the potential failure modes of batteries, testing for shock, impact, vibration, forced discharge, overcharge, overheating, short circuiting, and low pressure (high altitude) failures. It stands to be the foundation for the development of a durability standard as does IEC 62281 – Package Drop Testing.

9. Flame Spread vs. Fire Containment

Flame Spread does not equate to fire containment or fire resistance. Packs must meet the following standards:

– ASTM E119

– UL 1709

– UL 1642

– UL 1973

– UL 94 – Flame Spread

10. Toxicity

Lithium Prevent toxicity and flame spread: passes NASA Std. 6001: Upward Flame Propagation; Flammability Characteristics; Determination of Outgassed products; and SP-R-0022A Total Mass Loss and Collected Condensable Materials from Outgassing in a Vacuum Environment. The toxicity of a run away event with just a single cell is much less toxic than what results when the entire pack is consumed.