With global safety standards tightening, new expectations are being set for fire resilience in battery systems. This article breaks down what each regulation means, what’s changed, and how manufacturers can adapt—and stay compliant.

A New Era in Battery Fire Safety Standards

As global electrification accelerates, fire safety regulations are tightening to address the growing risks posed by lithium-ion batteries—namely thermal runaway, gas venting, and thermal runaway propagation (TRP). Four pivotal standards are reshaping the fire safety landscape:

- UL 9540A, 5th Edition – Energy Storage Systems (ESS)

- UL 9540B – Fire ignition and spread in residential ESS

- GB 38031-2025 – China’s enhanced regulation for EV battery safety

- UNECE R100.3 / IEC 62619 / ISO 12405 – Core European frameworks for EV and ESS battery systems

These standards are critical for engineers and safety professionals tasked with designing compliant, fire-resilient battery energy storage systems (BESS) and electric vehicles (EVs), including Battery Electric Vehicles (BEVs), Plug-in Hybrid Electric Vehicles (PHEVs), and Hybrid Electric Vehicles (HEVs).

While UL and GB dominate North American and Chinese regulatory environments, global OEMs must align with Europe’s UNECE R100.3 and IEC 62619 for access to EU markets.

Battery Energy Storage Systems (BESS)

As the global energy sector pivots toward electrification and renewable integration, BESSs have become essential infrastructure. These systems, often housing high-energy lithium-ion battery modules, are susceptible to thermal runaway and fire propagation—risks that demand robust passive fire protection. Compliance with testing standards such as UL 9540A is not only regulatory but vital to ensuring safe deployment.

Battery Electric Vehicle (BEV)

A BEV runs entirely on electricity. Unlike traditional cars, BEVs don’t have a gasoline engine; they get all their power from a rechargeable battery. This means BEVs produce zero tailpipe emissions, offering an environmentally friendly driving experience.

Plug-in Hybrid Electric Vehicle (PHEV)

A PHEV blends the best of both worlds: it has both a gasoline engine and an electric motor powered by a rechargeable battery. What makes it special is that you can plug it into an external power source to charge its battery, just like an all-electric car. This means you can drive on electricity alone for a significant range before the gasoline engine kicks in, or it can use both power sources together for maximum efficiency.

Hybrid Electric Vehicle (HEV)

A HEV operates by combining a gasoline engine with one or more electric motors and a battery. These vehicles intelligently switch between or combine these power sources to propel the car. This innovative design results in improved fuel efficiency and lower emissions when compared to conventional gasoline-only vehicles.

Standards Comparison: ESS vs. EV (Global Overview)

| Standard | Region | Sector | Focus Area | Key Change / Requirement |

|---|---|---|---|---|

| UL 9540A (5th Ed) | North America | ESS | Thermal runaway and propagation | Install-level testing required |

| UL 9540B | North America | ESS | Fire ignition and spread | Mandated gas ignition testing |

| GB 38031-2025 | China | EV | Passenger safety, alerting, housing | 2-hour TR delay, 5-min warning |

| IEC 62619 | Global/ EU | ESS | Battery cell/system safety | Comprehensive abuse testing, BMS protection |

| ISO 12405 | Global/ EU | EV | EV battery safety and lifecycle testing | Electrical, mechanical, and environmental stress |

| UNECE R100.3 | Europe | EV | Electrical safety, TR mitigation | Mandatory fireproof housing & system separation |

Fire Safety for ESS: Deep Dive into UL 9540A and 9540B

UL 9540A (5th Edition): Reinforcing Thermal Runaway Mitigation

UL 9540A now requires thermal event testing across cell, module, unit, and full installation levels, ensuring end-to-end propagation assessment in operational settings.

Key Technical Enhancements:

- Expanded Scale Requirements: Testing now spans cell, module, unit, and installation levels—with emphasis on in situ fire propagation.

- Gas Flow & Composition Analysis: Enhanced tracking of hydrogen, CO, and hydrocarbon gases for explosion modeling.

- No Assumed Ignition: Allows gas release without ignition, which challenges real-world fire suppression planning.

Why It Changed:

Earlier versions fell short in simulating field conditions. Authorities Having Jurisdiction (AHJs) called for testing that reflects full-system behavior in populated areas. The 5th Edition closes this gap but doesn’t fully address fire ignition.

Test Setup Examples:

- Cell-Level: Heat to failure, analyze gases via chromatography.

- Module-Level: Heater pad-induced thermal runaway.

- Installation-Level: Simulate full-rack TRP and overpressure.

Design Implications for OEMs:

- Material Engineering: Specify intumescent polymers like TemprCore™ that offer thermal insulation and structural integrity above 800°C.

- System Architecture: Optimize rack design for spacing, flame containment zones, and vertical venting.

- Project Timeline Impact: The broadened scope demands early material selection and simulation planning to prevent downstream certification delays.

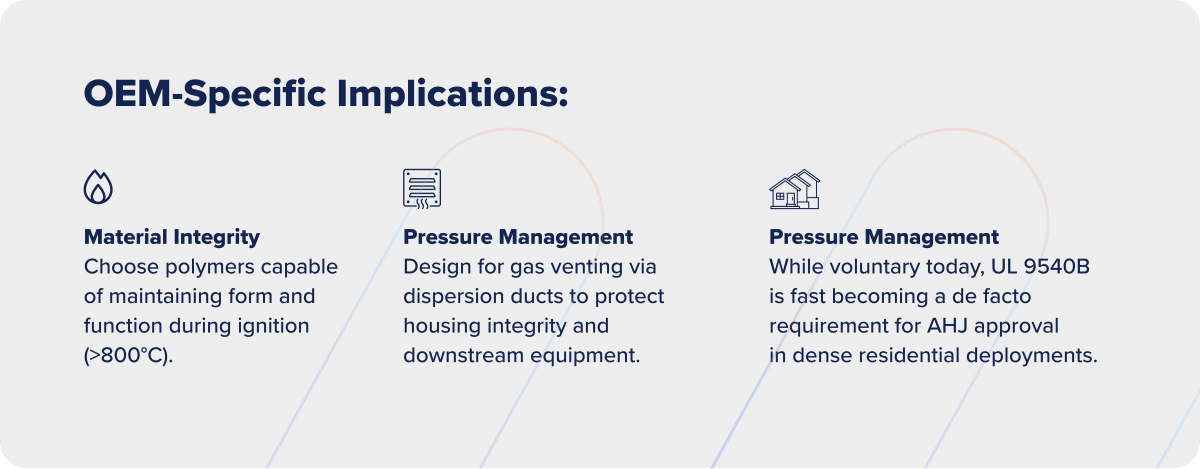

UL 9540B: Residential ESS Fire Testing

UL 9540B mandates ignition testing of off-gases in residential energy storage systems.

Core Features:

- Targeted Ignition: Flame ignition, spread, and enclosure failure.

- Scope: Cell- and install-level only.

- Purpose: Increase readiness for first responders.

Design Implications for OEMs:

- Use SafePassage™ for cable and pipe penetration zones to prevent flame spread.

- Integrate pressure relief panels in residential ESS enclosures.

- Pre-validate housing materials for sustained flame resistance and mechanical durability under thermal load.

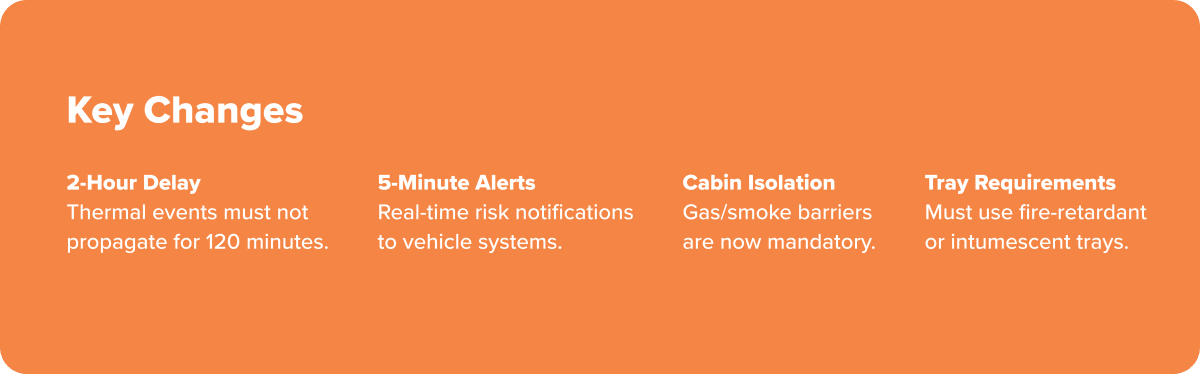

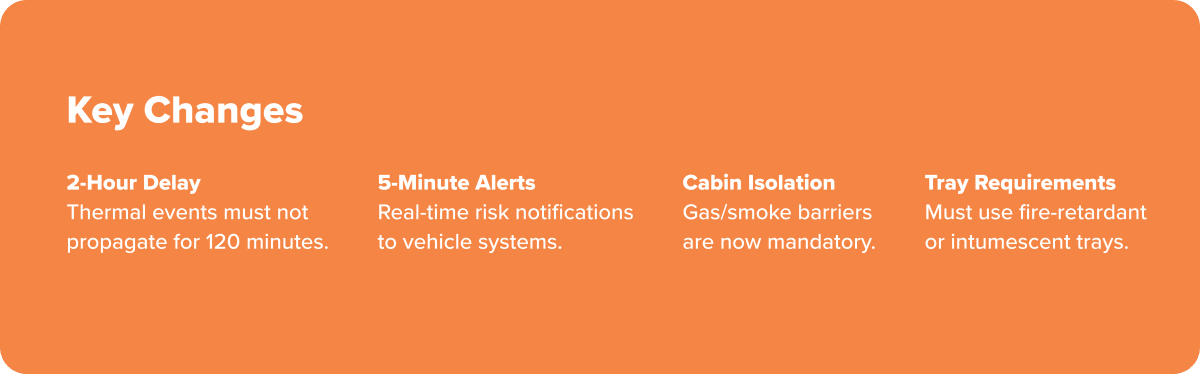

GB 38031-2025: EV Fire Safety Leadership from China

China’s upgraded regulation enhances early warning and containment for high-voltage EV batteries.

OEM Insight: Compliance with GB 38031-2025 is mandatory for accessing China’s EV market. Noncompliance may result in rejection from type approval, even if previous standards were met.

Design Recommendations:

- Integrate LithiumPrevent™ as a physical barrier between modules to prevent TRP.

- Apply smoke-tight gaskets and intumescent seals in battery-cabin interfaces.

- Model enclosure behavior with ISO 12405 simulations to validate performance.

European Frameworks: What Global Manufacturers Must Know

IEC 62619 (ESS)

Defines test protocols for rechargeable battery safety, including:

Short circuit, overcharge, mechanical, thermal abuse

BMS diagnostics and protective circuitry

ISO 12405 (EV)

Evaluates:

Battery cycling, vibration resistance, crash response

Connector integrity and enclosure performance

UNECE R100.3 (EV)

Specifies:

Enclosure flame resistance

Isolation resistance

Fireproofing for system containment zones

OEM Note: UNECE R100.3 is required for type approval in the EU. Early alignment reduces redesign risk during homologation.

Pyrophobic Solutions for Fire Compliance

Pyrophobic’s material science platforms deliver regulation-ready performance:

- LithiumPrevent™ — Battery tray and module dividers for GB 38031-2025, R100.3.

- TemprCore™ — Rack-level fire insulation for UL 9540A installations.

- SafePassage™ — Penetration protection for 9540B, E814, and UL 1479 compliance.

Final Word: Don’t Just Catch Up. Lead.

Design for safety today to lead in compliance tomorrow. With increasing international alignment, only proactive engineering meets the fire resilience benchmark.

Be safe. Be certified. Be Pyrophobic.