The rapid expansion of lithium-ion battery use in electric vehicles (EVs) and grid-scale energy storage systems (ESS) is reshaping our energy infrastructure. The IEA’s ‘Batteries and Secure Energy Transitions‘ report provides an in-depth analysis of the battery market and the importance of batteries in the modern energy sector. It also highlights the importance of policy regarding lithium-ion battery fire safety. As deployments grow, so does the need for reliable fire protection. Addressing thermal runaway and implementing proactive safety measures are essential to ensuring the long-term viability of these technologies. This article explores advanced strategies and materials designed to move beyond traditional suppression methods—focusing on early detection, containment, and system-level resilience.

Moving Beyond Thermal Runaway Triggers: Predictive and Diagnostic Tools

While understanding the triggers of thermal runaway remains essential, the future of lithium battery fire protection lies in predictive modeling and system-level diagnostics. We need to anticipate potential failures, enabling proactive intervention and mitigating risks before they escalate.

Analysis of Thermal Runaway and its Catastrophic Consequences

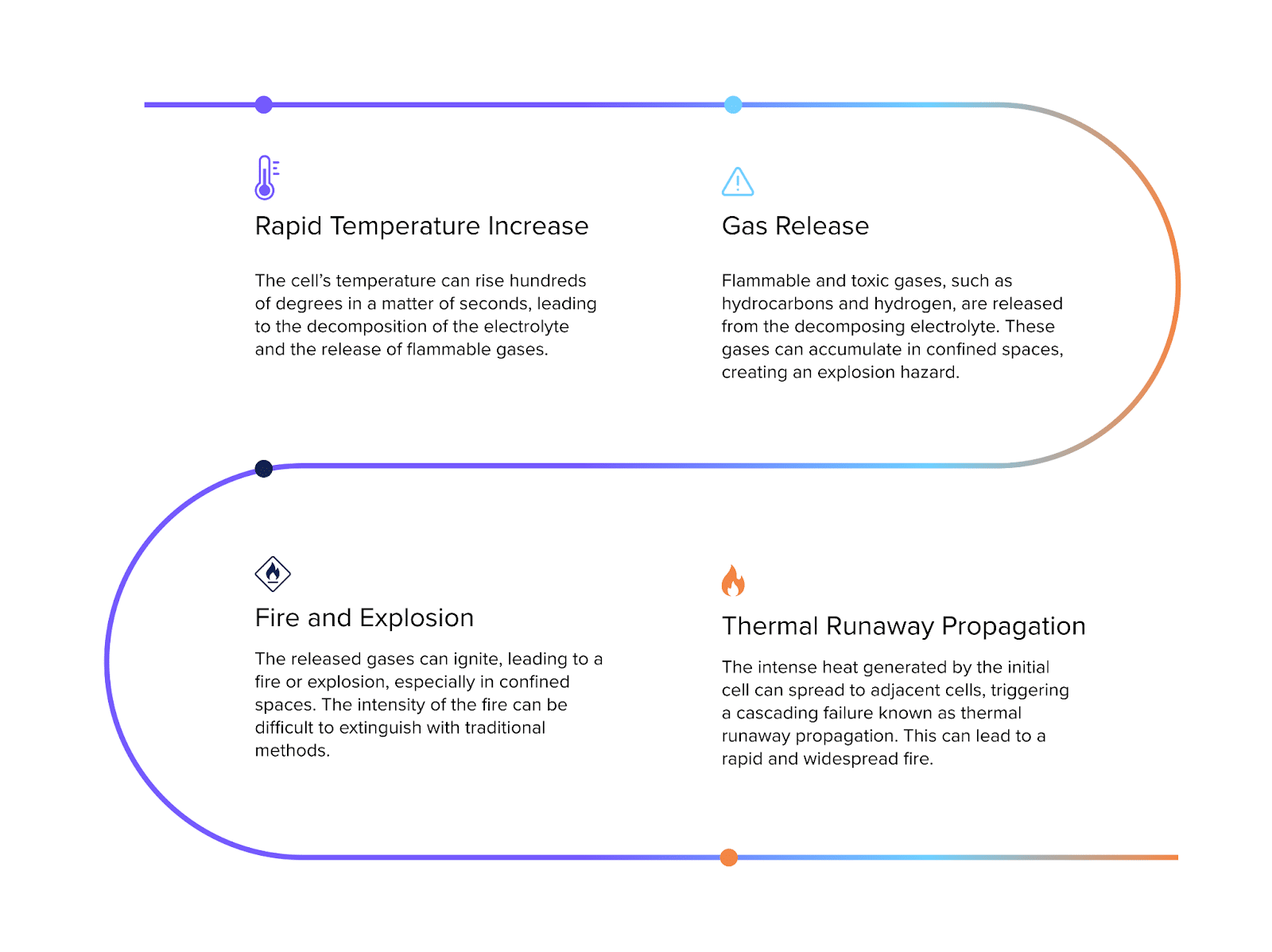

Before diving into predictive tools, it’s crucial to understand the devastating impact of unchecked thermal runaway. Once initiated, the cascading exothermic reaction leads to severe and potentially catastrophic consequences:

- Rapid Temperature Increase: The intense heat generated leads to the rapid and uncontrollable escalation of temperatures across the entire battery system.

- Gas Release: The release of flammable and conductive gases creates the potential for explosions and the spread of fire to surrounding areas.

- Fire and Explosion: The resulting fires and explosions can lead to a positive feedback loop that can cause the complete destruction of battery storage systems and vehicles.

- Cell-to-Cell Propagation: The propagation across interconnected cells leads to the rapid and widespread destruction of the entire battery system.

AI-Driven Predictive Modeling:

Advanced artificial intelligence (AI) and machine learning (ML) algorithms can analyze real-time data from battery management systems (BMS) and environmental sensors. This includes monitoring voltage, current, temperature, and impedance, as well as external factors like ambient temperature and humidity. By training these algorithms on vast datasets of battery performance and failure modes, subtle patterns and anomalies that indicate impending thermal events can be identified, allowing for timely intervention. For example, AI algorithms can recognize specific impedance changes that precede internal short circuits, enabling proactive cell replacement or system shutdown. This approach aligns with recent research that emphasizes the critical role of machine learning in predicting battery failures and enhancing safety, as detailed in a comprehensive review.

Advanced Sensor Networks for System-Level Diagnostics:

Sophisticated sensor networks can monitor the overall health of battery systems at the module and pack level. This includes deploying distributed temperature sensors, voltage probes, and impedance analyzers to provide comprehensive real-time data. Integrating these sensor networks with edge computing and cloud-based analytics platforms facilitates continuous monitoring and data processing, enabling early detection of potential failures. Distributed fiber optic temperature sensors, for instance, can provide high-resolution temperature mapping of battery modules, identifying localized hotspots that indicate potential thermal runaway initiation.

Emerging Battery Chemistries and LithiumPrevent Solutions

Developing battery chemistries with inherently higher thermal stability and fail-safe mechanisms is being explored. This includes solid-state electrolytes, which eliminate flammable liquid electrolytes, and advanced separators with improved thermal resistance and mechanical strength, all contributing to enhanced lithium-ion battery fire safety.

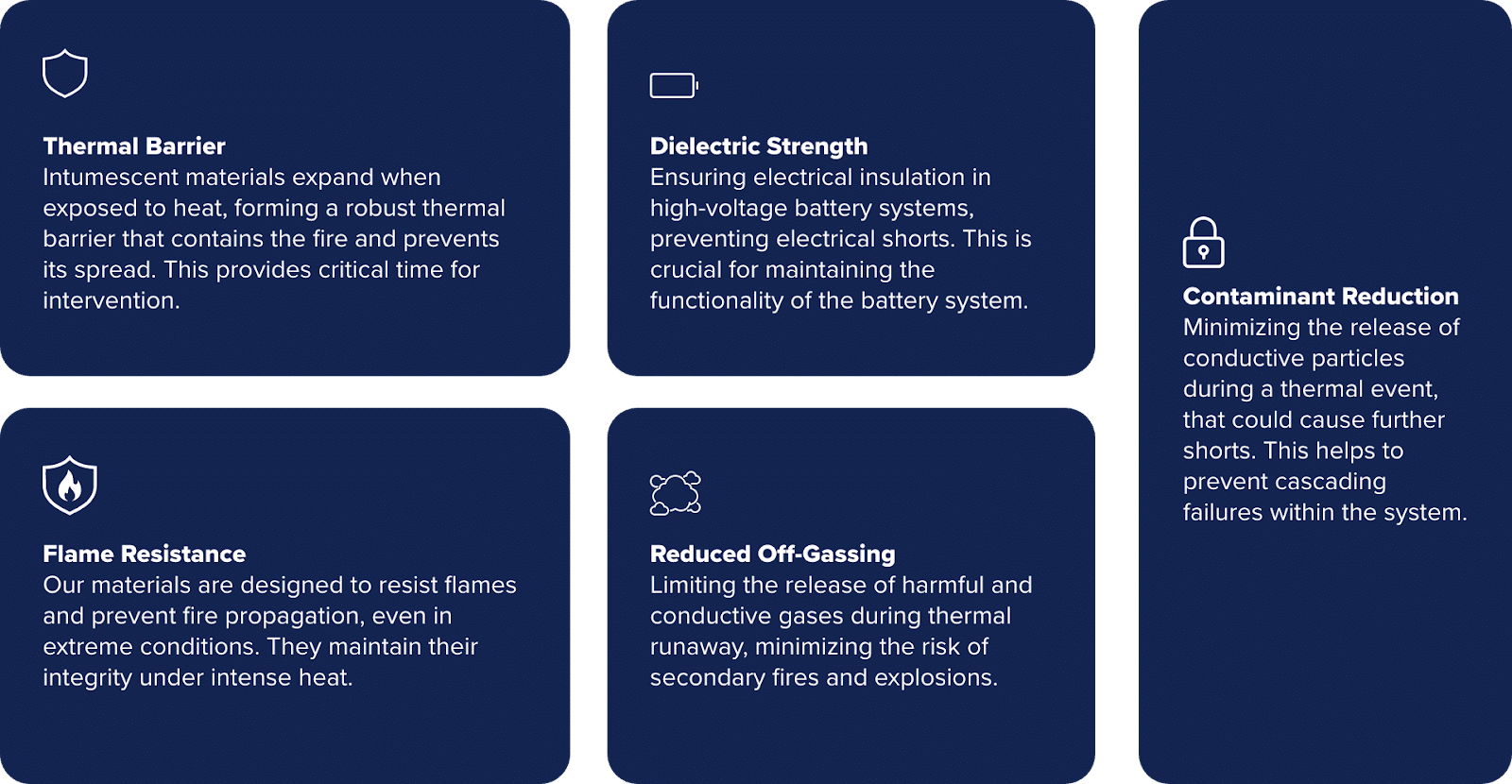

Furthermore, specialized material solutions like LithiumPrevent offer engineered protection through advanced intumescent materials. These materials provide:

- Intumescent Thermal Barrier: Expanding significantly when exposed to heat, LithiumPrevent forms a robust and insulating char layer that effectively contains fire spread. This intumescent reaction is endothermic, actively absorbing energy from the thermal event and contributing to a cooling effect. The substantial expansion of the char also has the potential to limit oxygen availability to the source of the event.

- Flame Resistance: LithiumPrevent maintains structural integrity under extreme heat, forming a durable char layer that is both non-friable and porous. This robust char acts as a stable barrier, significantly hindering flame propagation and protecting underlying components.

- Dielectric Strength: Critically, LithiumPrevent delivers dielectric strength, a feature not universally present in all intumescent materials, preventing electrical shorts in high-voltage systems.

- Reduced, Non-Conductive, Non-Flammable Off-gassing: While all intumescent materials release off-gases during thermal decomposition, LithiumPrevent is specifically engineered to release off-gases that exhibit significantly lower conductivity compared to other thermoplastic solutions. Furthermore, these off-gases are non-flammable, offering a substantial safety advantage.

Material-Driven Prevention: Beyond Traditional Suppression

Traditional fire suppression methods, like water or foam sprinklers, often prove inadequate and potentially problematic for lithium-ion battery fires due to the unique chemical and thermal characteristics of these events. While not strictly identical in all respects, lithium-ion battery fires share characteristics with Class D fires, which involve combustible metals – in this case, lithium. Class D fires burn at extremely high temperatures, and applying water can be ineffective or even dangerous, potentially reacting violently, causing explosions, or spreading flammable materials.

These factors highlight why a shift towards material-driven prevention strategies is crucial. Addressing the root causes of thermal runaway through containment and inherent material safety, rather than relying solely on post-ignition suppression, offers a more reliable and often more cost-effective approach to ensuring the safety and resilience of lithium-ion battery deployments.

Advanced Intumescent Materials for Optimized Containment:

Intumescent materials with tailored expansion rates and char formation properties are being developed to optimize heat dissipation and gas containment. Engineering materials with specific thermal conductivity, flame resistance, and gas barrier properties effectively manage the heat and flammable gases released during thermal runaway. Nanoparticle additives to enhance thermal conductivity and char formation are examples.

Integrated Thermal Management for Temperature Regulation:

Battery modules with integrated thermal management systems that actively regulate cell temperatures and prevent localized hotspots are being designed. This includes incorporating liquid cooling channels, heat pipes, and phase change materials (PCMs) to efficiently dissipate heat and maintain uniform temperature distribution across the battery pack. Microchannel liquid cooling systems and PCM-enhanced thermal interfaces are examples.

Smart Coatings for Responsive Anomaly Detection:

Smart coatings that can detect and respond to thermal anomalies, triggering localized cooling or fire suppression mechanisms, are being applied to battery components. Coatings with embedded sensors and actuators that can release cooling agents or fire suppressants in response to temperature spikes or gas emissions are being developed.

Gaseous Suppression at the Cell Level:

Gaseous suppression agents that can be released at the cell level in the event of thermal runaway to suppress the fire before it propagates are being researched and developed. This involves exploring the use of non-flammable gases with high cooling capacity and fire suppression effectiveness and designing integrated release mechanisms that thermal or chemical sensors can trigger. Integrated microvalves and gas reservoirs within battery modules are examples.

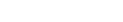

Building a Resilient Energy Future: Collaboration and Innovation

LithiumPrevent delivers a robust solution for current fire protection needs, directly strengthening the resilience and safety of advanced energy storage systems. This development highlights the power of collaborative innovation in addressing critical challenges within the energy sector.